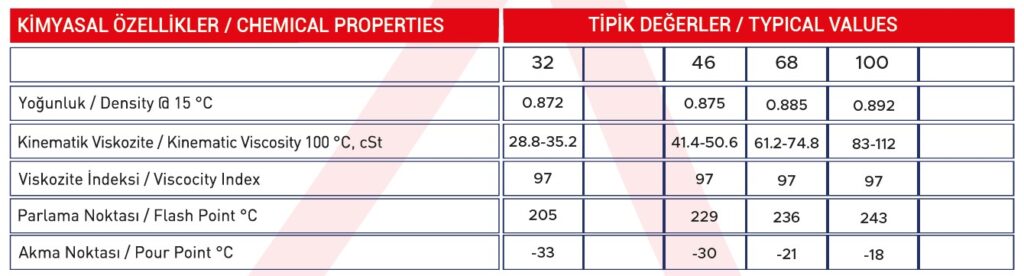

Compressor oils designed for compressors operating under moderate and heavy conditions, formulated with high quality mineral base oils and high performance additive system. Excellent oxidation resistance has a tendency to form low soot and they easily separate from water. They perform very well in lubricating compressor systems with gears and bearings and are thus widely used. Recommended for single and multi-stage air compressors. They are successfully used in piston air compressors crankcase and cylinders, screw compressors, vane compressors, axial and centrifugal compressors, compressor systems with critical gears and bearings, compressors used in fixed and mobile applications. Low viscosity products are more suitable for rotary type compressors, while high viscosity products are recommended for crawler and piston compressors. Compressor manufacturer’s recommendations should be followed when selecting the required degree of viscosity. Ensures long oil life thanks to heat and oxidation stability. It is designed to provide anti-corrosion, anti-wear and extreme pressure properties. It ensures maintenance and oil saving thanks to the additives it contains. Extends oil change intervals (up to 4000 hours). It provides excellent temperature stability even under high operating conditions. It prevents sludge formation thanks to its zinc-free technology. It provides high performance thanks to its improved water and air separation capabilities.

Comment